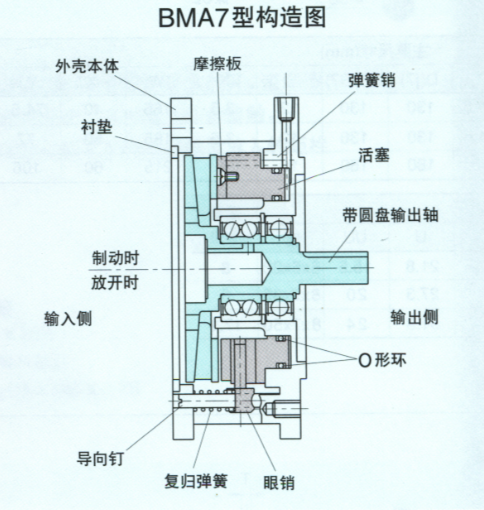

Structure:

1. The brake connects with flanged motor directly and time consumption cost in assembly is thus reduced.

2. The input end of BMA Brake can be directly installed to standard flanged motor, air actuated brake would be assembled when the output end of BMA Brake is equipped with component such as reducer.

3. The flange surface with input power bearing can be easily equipped with reducer and other components. Effective heat releasing is guaranteed due to the application of flat rated disc and the brake is thus appropriate for highly frequent application.

Parameter of BMA(Template Type) Brake

|

Aur clutch |

Static friction torsion(N.m) |

Critical dimension(mm) |

||||

|

Model |

0.6MPa |

ID A |

OD B |

Total length C |

Revolution limit r/min |

Weight kg |

|

BMA7-119MN |

65 |

19 |

200 |

114.5 |

1800 |

8 |

|

BMA6-124MN |

65 |

24 |

200 |

124.5 |

1800 |

8 |

|

BMA12-128MN |

120 |

28 |

250 |

166 |

1800 |

17.1 |

Parameter of BMN(Template Type)Brake

|

Air clutch |

Static friction torsion(N.m) |

Critical dimension(mm) |

||||

|

Model |

0.6MPa |

ID A |

OD B |

Total length C |

Revolution limit r/min |

Weight kg |

|

BMN6-124MN |

65 |

24 |

200 |

211 |

1800 |

11.4 |

|

BMA12-128MN |

120 |

28 |

250 |

285 |

1800 |

22.3 |