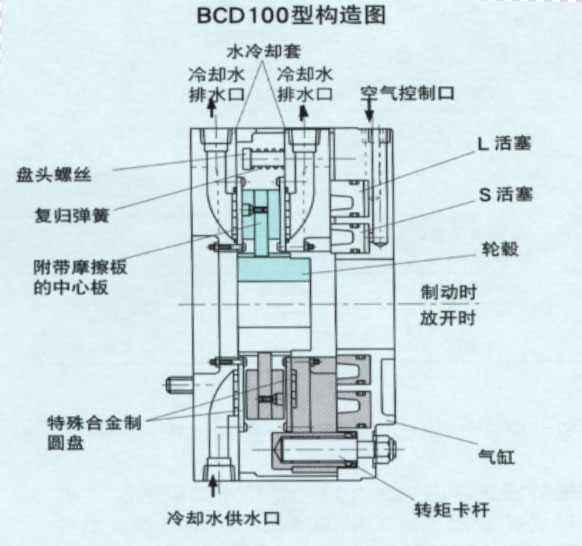

Structure:

1.Two pistons of different sizes are configured in concentric shape on the same side of BCD Air Brake.

2.There is a center plate with friction plate rotating with the shaft between the water cooling sleeve pressurized by the piston and the fixed side of water cooling sleeve.

3.Each water cooling sleeve is equipped with a special alloy disc which is cooled by water and thus guarantees its good heat conductivity.

4.BCD 100 is equipped with 2 friction plates, BCD200 is equipped with 4 friction plates, and BCD 300 is equipped with 6 friction plates.

When air is fed inside, piston presses the water cooling sleeve on the pressurized side; center plate attached with friction plate is also pressed and contacts water cooling sleeve on the fixed side.

When air is discharged, brake is released by resetting the spring. Two pistons of different sizes in BCD Air Brake can move either separately or simultaneously.

Parameter of BCD (Water cooled & Multiple Plates) Brake

|

Air clutch |

Dynamic friction torsion(N.m) |

ID A |

OD B |

thickness G |

Revolution limit |

Weight kg |

|

|

Model |

0.6MPa |

Btm. hole |

Max. (key dimension) |

r/min |

|||

|

BCD 120 |

520 |

40 |

60(18×11) |

308 |

152 |

2200 |

45 |

|

BCD 220,X |

1040 |

40 |

60(18×11) |

308 |

222 |

2200 |

68 |

|

BCD 130 |

1570 |

50 |

120(32×18) |

420 |

175 |

1350 |

83 |

|

BCD 230,X |

3140 |

50 |

120(32×18) |

420 |

250 |

1350 |

128 |

|

BCD 330 |

4710 |

90 |

120(32×18) |

420 |

323 |

1350 |

186 |